13" DTF Printer

No reviews

/

Shipping calculated at checkout.

13" DTF Printer with Dual XP600 Printheads - $8,000,00 Complete Setup with Printer, Powder shaker, Oven, and Cooling Fan. 4-8 Weeks Lead Time shipped directly to your door. Comes completed with hosonsoft or Sun Yang and MainTop RIP Software.

SHIPPING INCLUDED IN PRICE!

SHIPPING INCLUDED IN PRICE!

High productivity

This type of printer printing width max 61cm,

Epson Printer Head

Our printer used Epson printer head, xp600

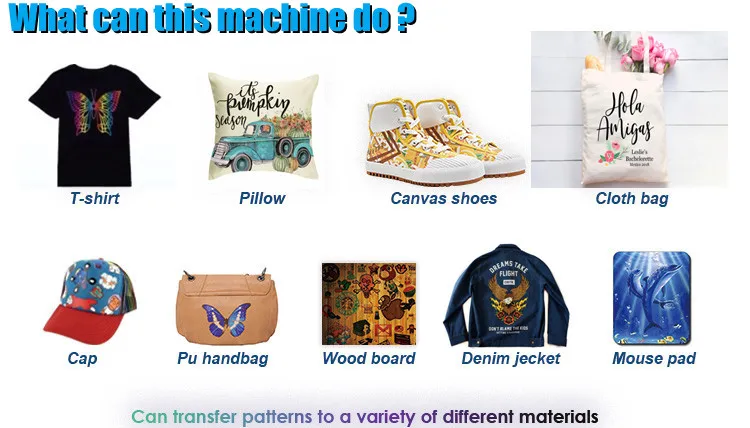

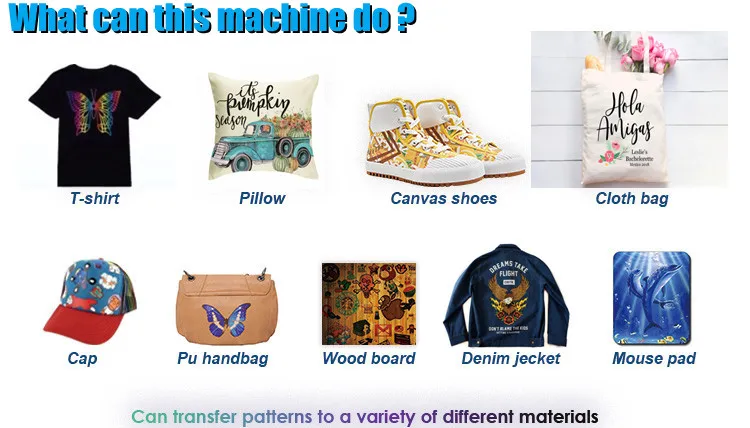

Widely Use

Works with almost all types of fabrics.

6 month Warranty

We will provide you instant online support service and free repair service.

This type of printer printing width max 61cm,

helping you greater output from the same time amount of input.

Epson Printer Head

Our printer used Epson printer head, xp600

Widely Use

Works with almost all types of fabrics.

6 month Warranty

We will provide you instant online support service and free repair service.

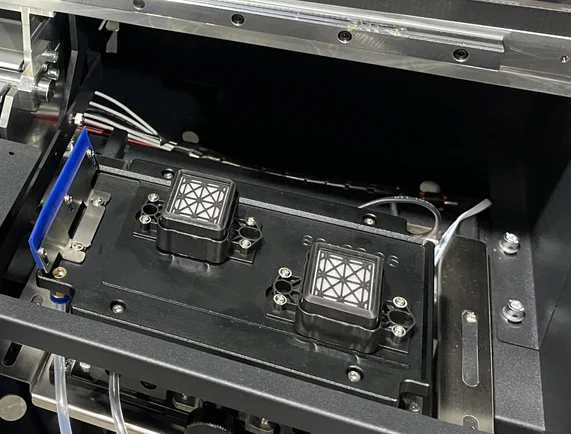

Epson Print Heads Optional

• XP600 Original Print Heads • High density and longer service life

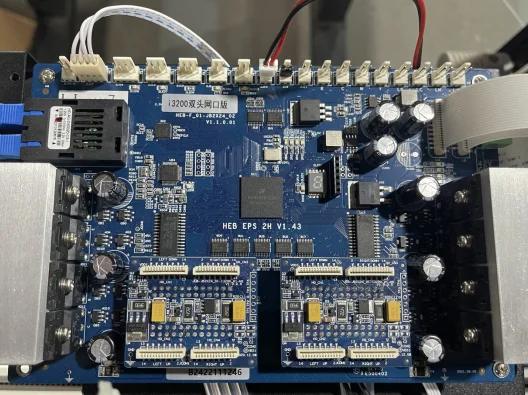

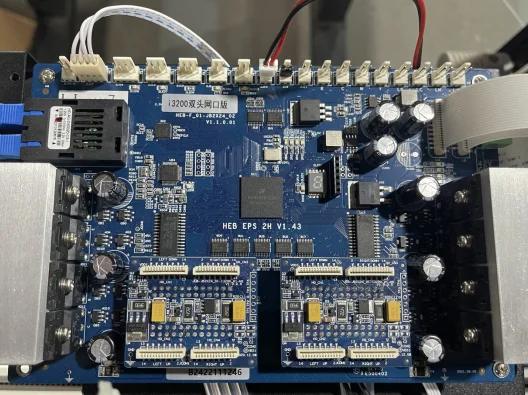

Hoson/Senyang Main Board

• More fuctions • Operation more convenient and stable

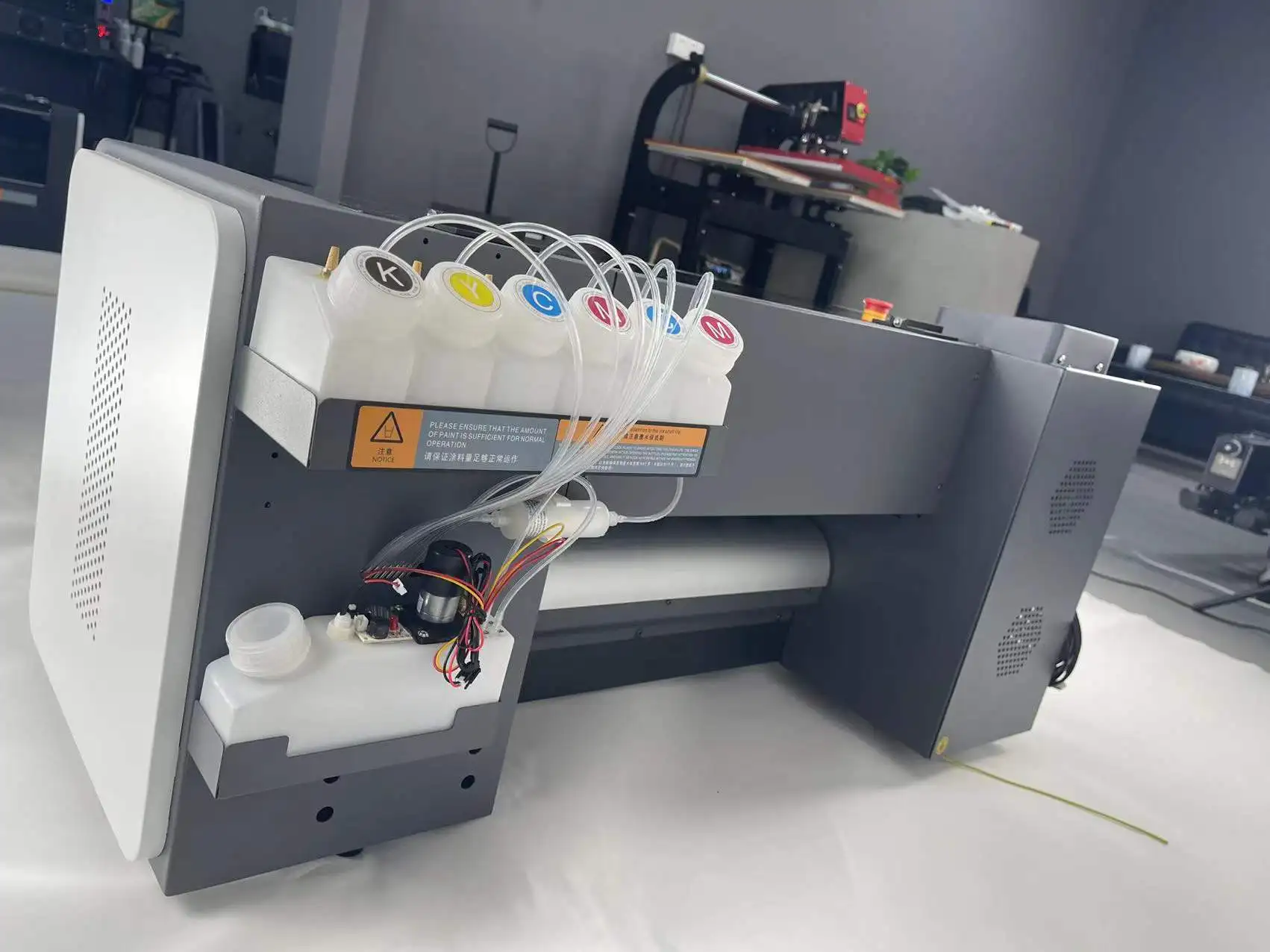

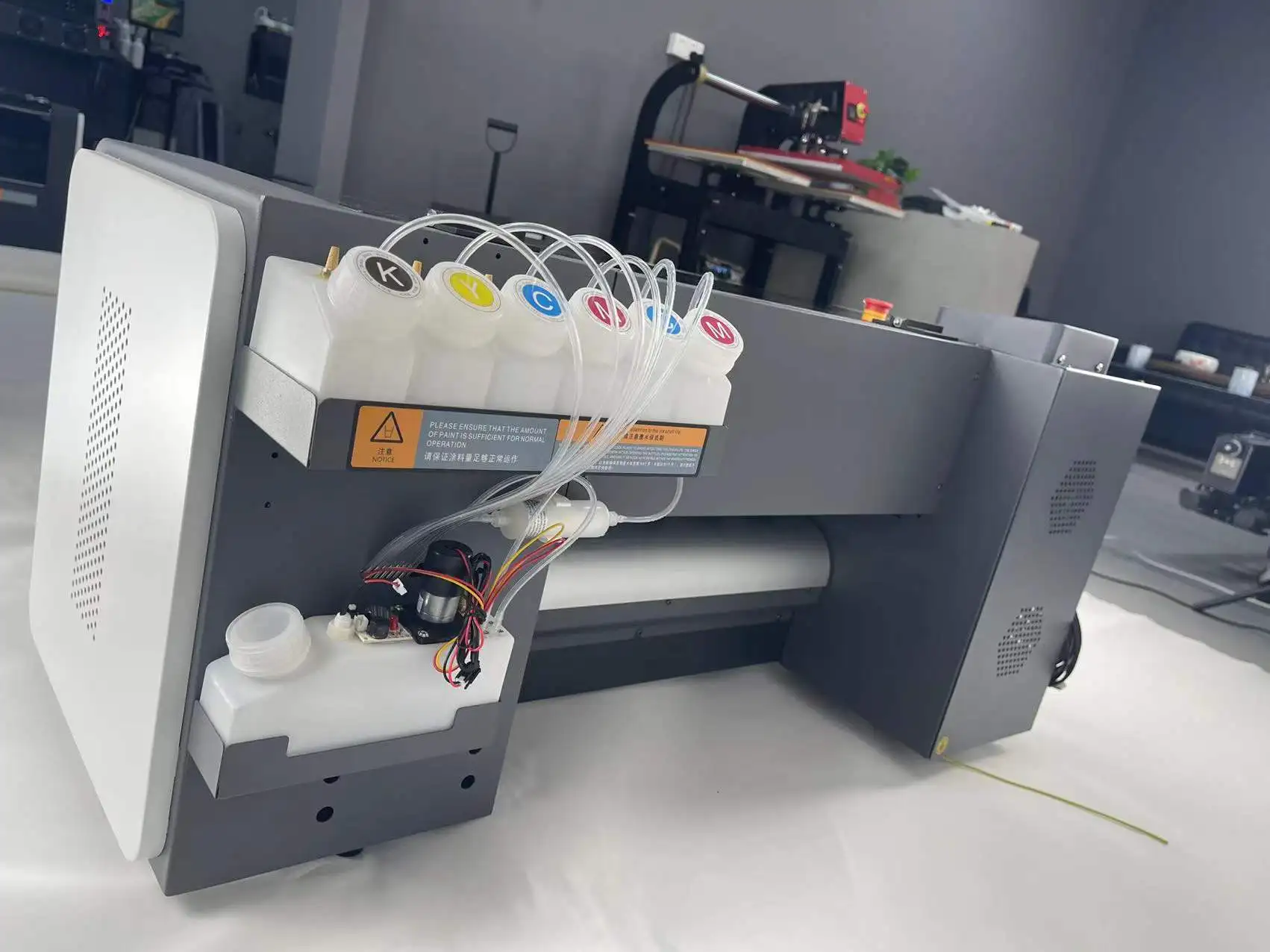

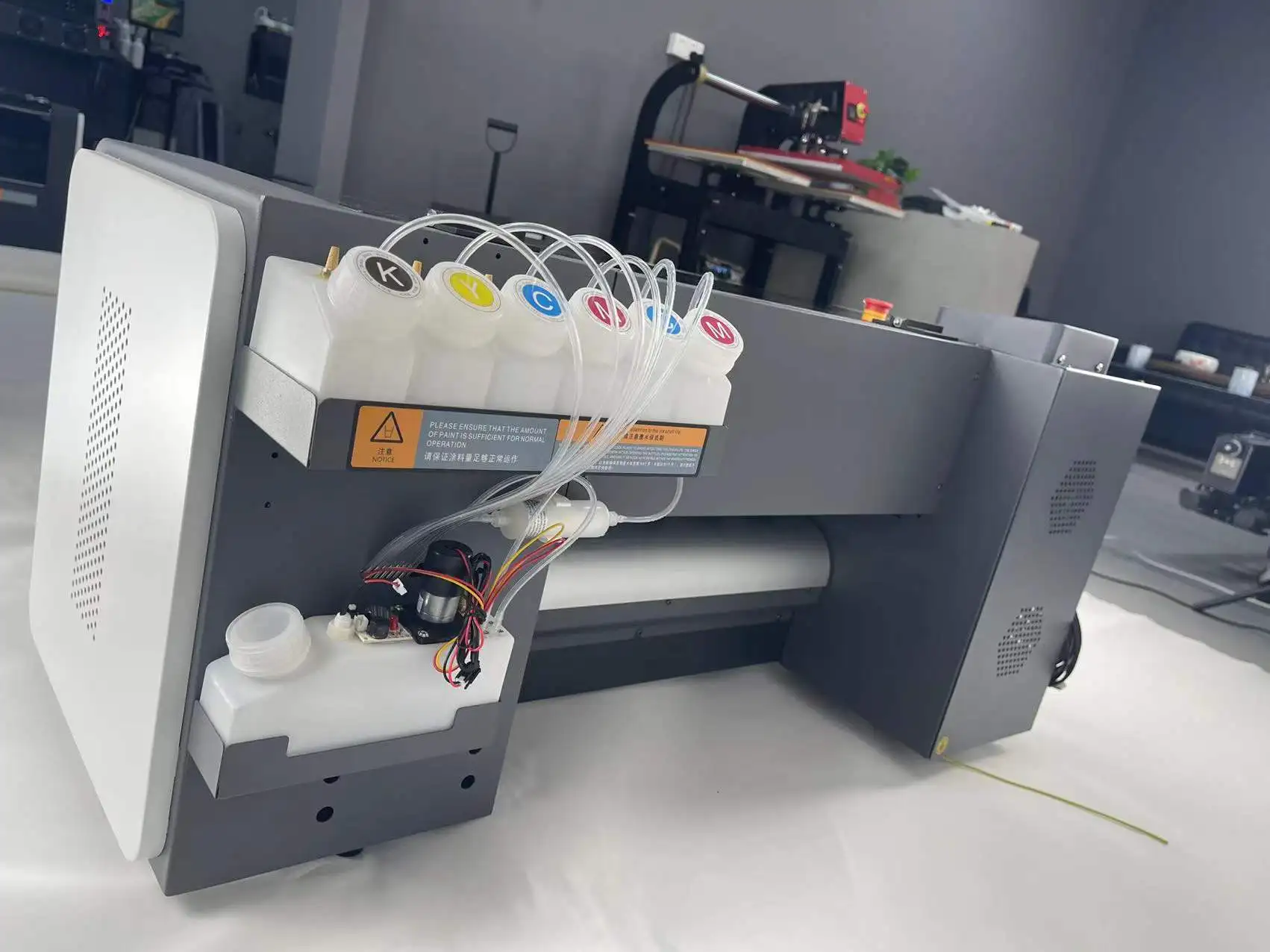

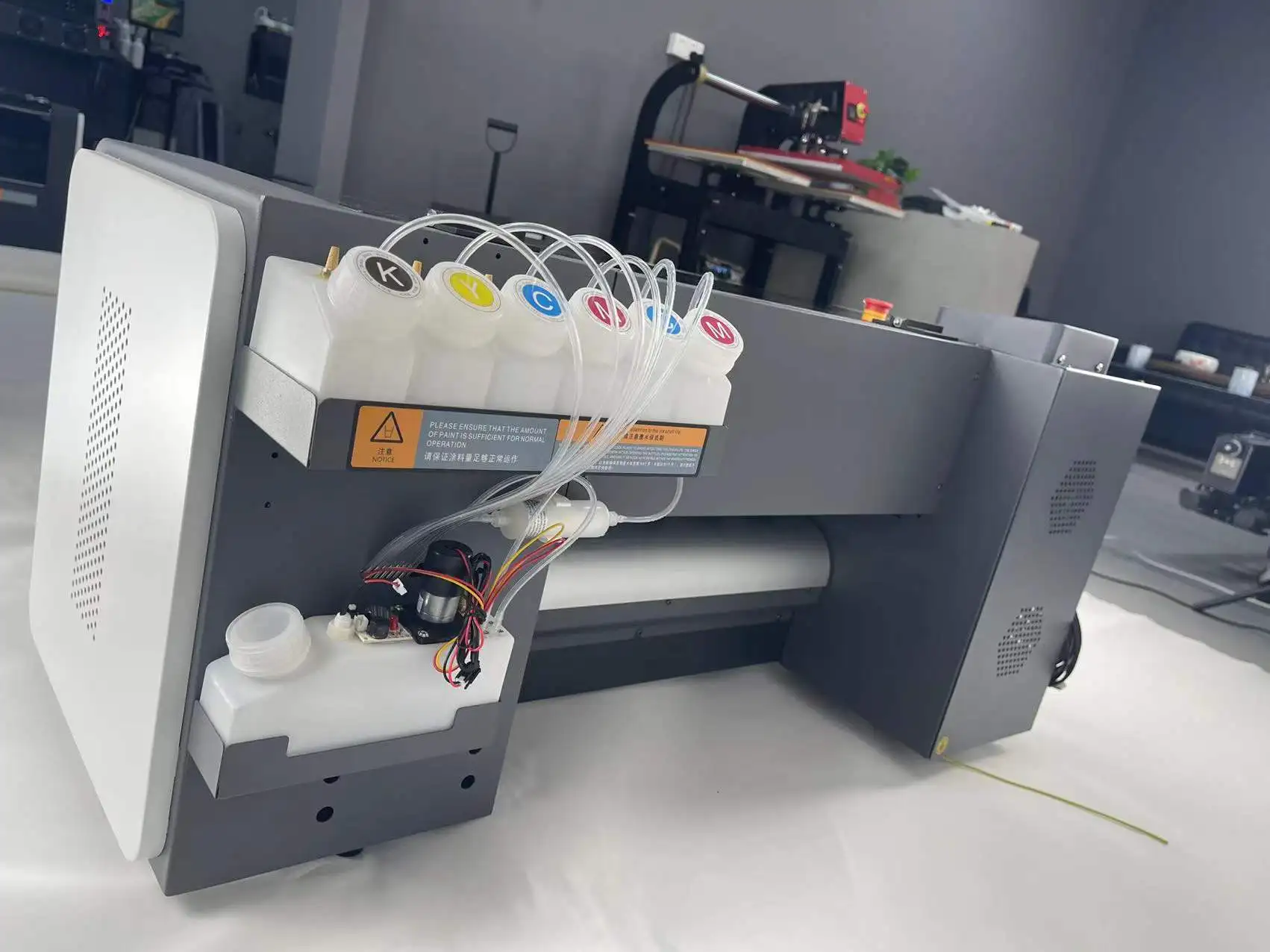

Ink Cartridge System & Alarm Device

• Support CMYK LcLm W • Large capacity for constant pressure ink supply • Alarm device to avoid ink shortage

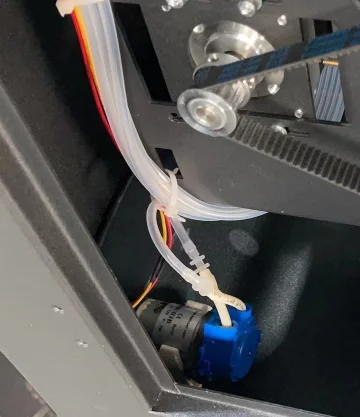

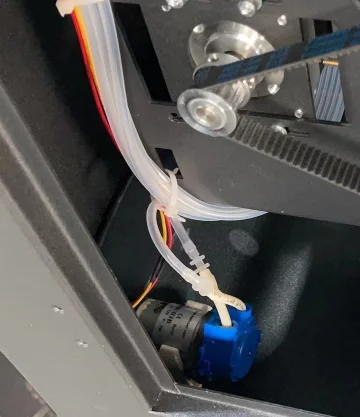

White ink Stirring

• Automatically and intermittently stirs the white ink • Keep printing color uniform • Keep the nozzle unclogged

White ink Circulation

• Attached with circulating pump,

• circulate the ink in the pipeline to prevent blockage

White ink Stir & Circulation

• Separate button

• Stir and circulation can be adjusted

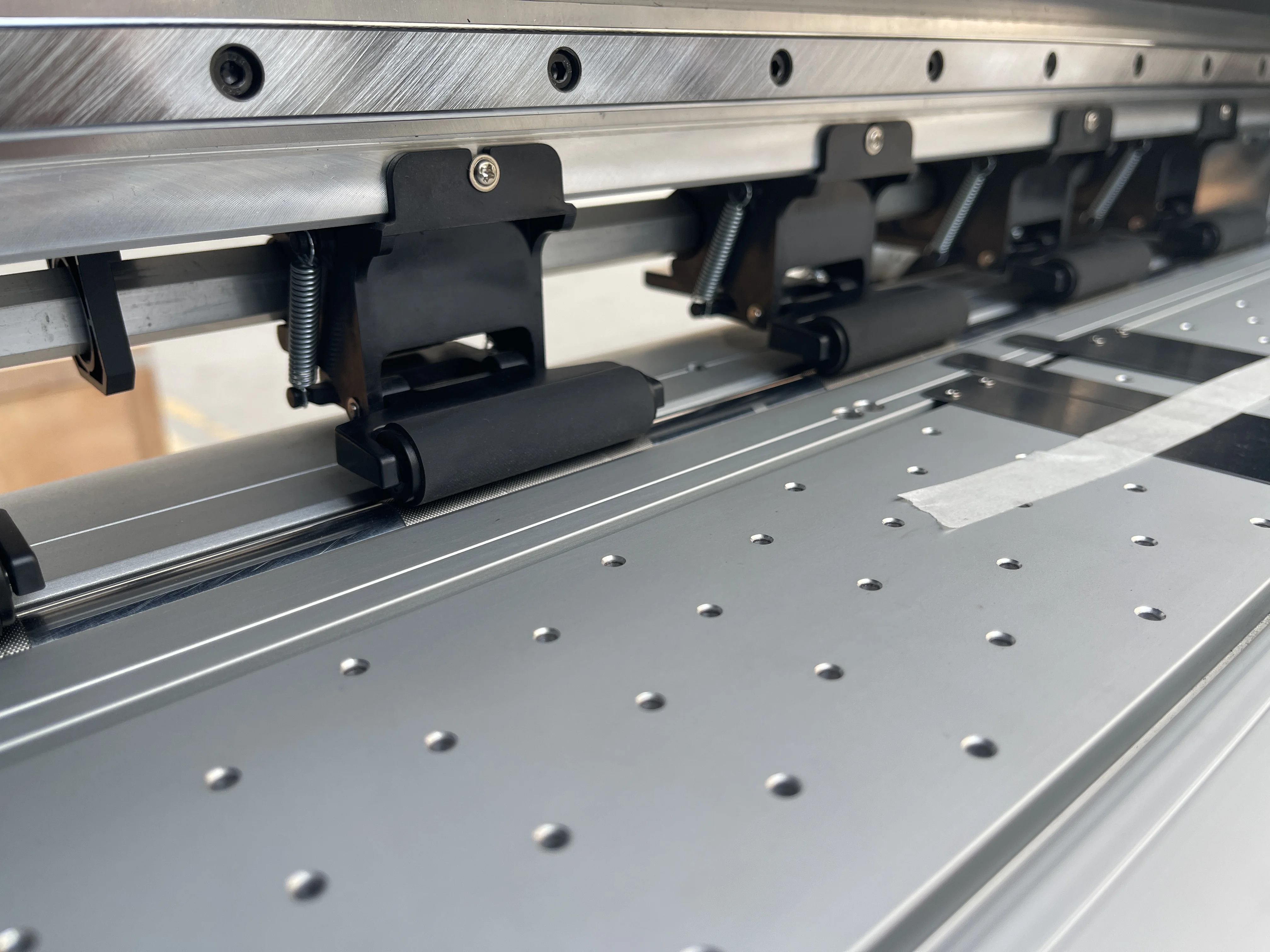

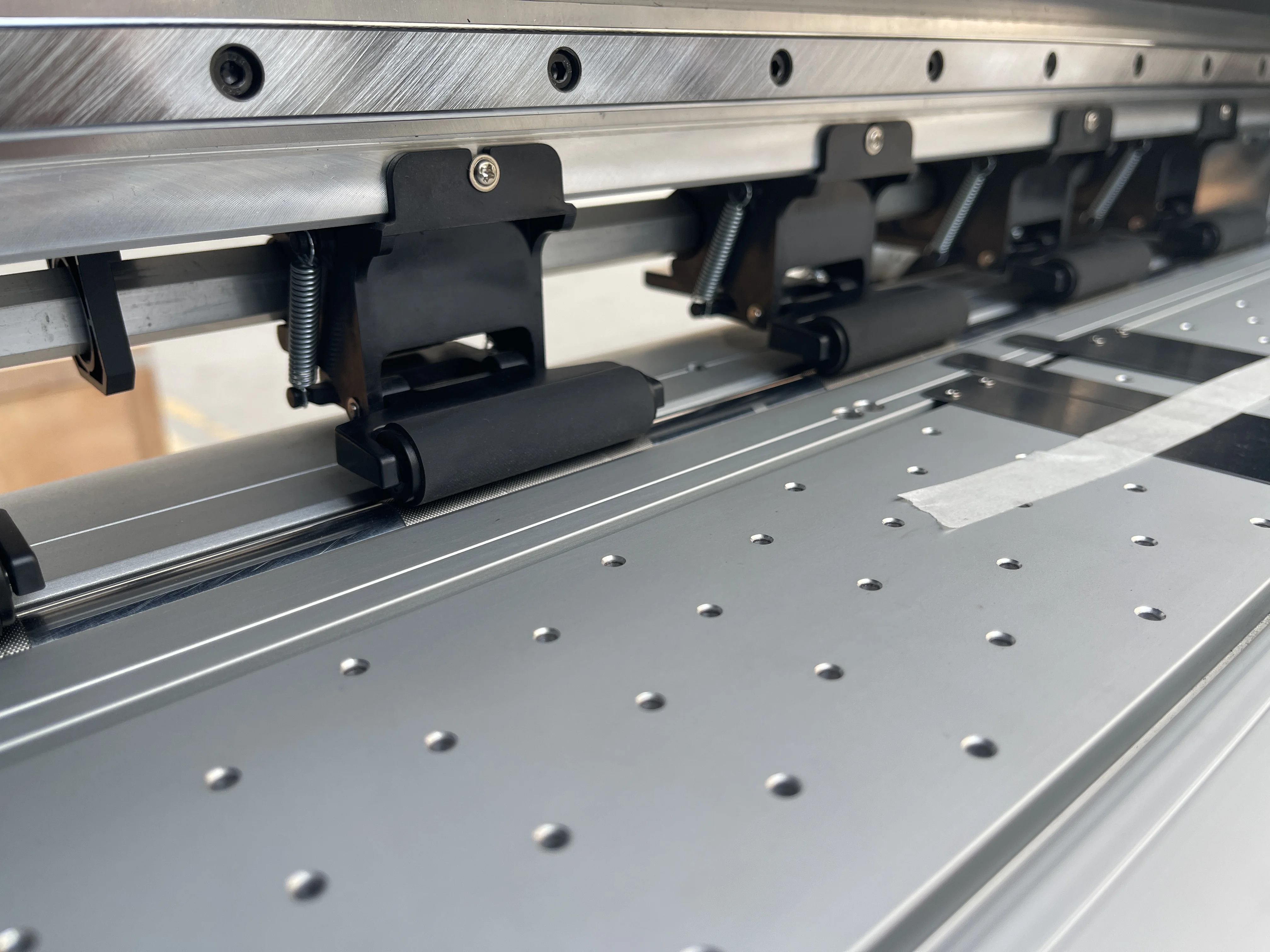

Japan THK Linear Guide Rail

• Front and rear arc plate heating • 3-way constant temperature

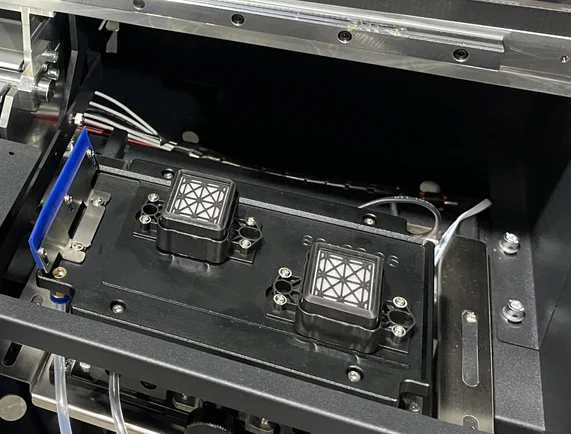

Elevation Capping Station

• Protect print heads • Lifting ink stack, more accurate and durable

Suction Platform

• Ensure material flatness • Improve smoothness of paper feeding • Ensure stability of printing

Control Panel

• Easy to operate • More functions available

Suction Platform

• Ensure material flatness • Improve smoothness of paper feeding • Ensure stability of printing

Automatic Induction Winding

• Automatic induction winding fuction • saving time, effort and labor

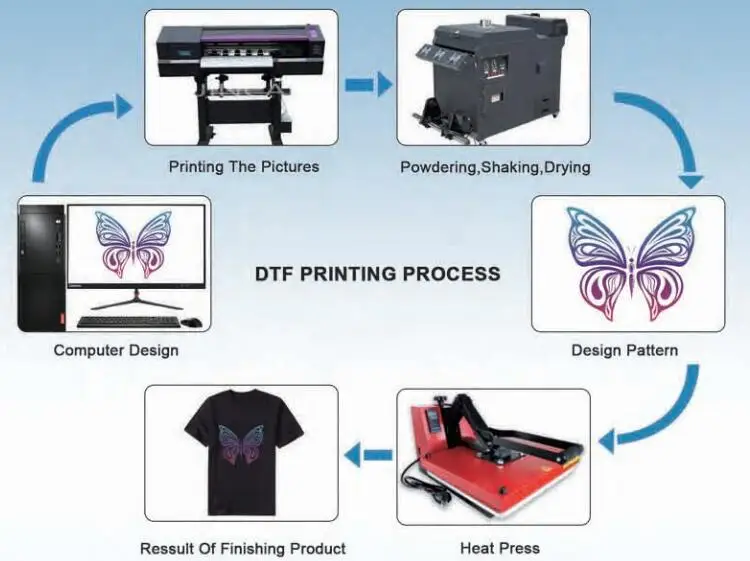

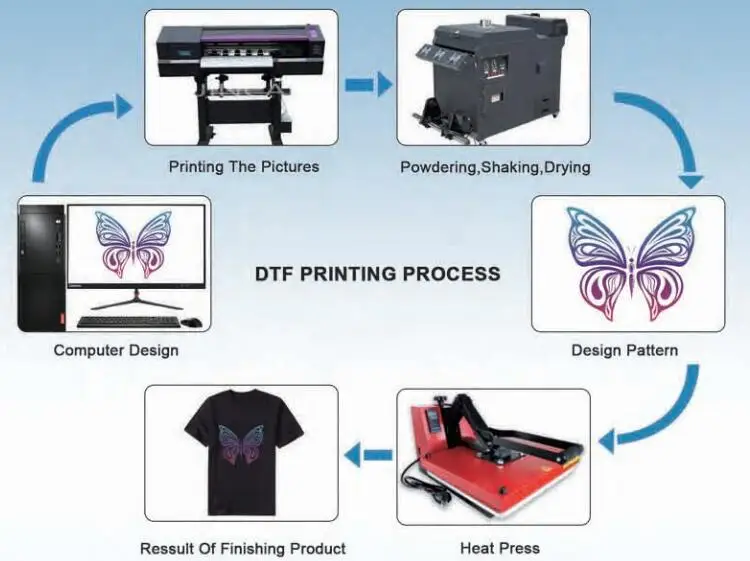

The DTF process is as simple in its working as its name suggests -

Print on a film and directly transfer onto fabric.

1. Design Pattern

1. Design Pattern

Use photoshop, illustrator or other software to design your pattern

2. Print your design

Ajust the printer parameters in the RIP sofware and use ink to print your pattern to the film

3. Powdering

Turn on the switch of powder shaking machine, the machine will automatically powdering, shaking ,

drying and fix the color

drying and fix the color

4. Heat Press

Use a heat press machine, set the temperature to 150 degree, and time 12 seconds to transfer